Does the idea of checklists sound limiting? Well, buckle up. Preventive maintenance checklists might just be the thing that flips that idea on its head.

If you’ve ever been faced with a task and found yourself overwhelmed by the number of ways to complete it, you know how freeing a little guidance can be.

Well crafted preventive maintenance checklists give your team the step-by-step tools they need to be successful. Checklists can also help them complete tasks more thoroughly, freeing them up for their next task faster. We’ll show you how to make the most of them.

An official Standard Operating Procedure (SOP) that demonstrates the best way to complete a regular inspection or routine maintenance task has many benefits. Here are the top four.

There are many wrong ways to do a job. There may also be many ways to do a job right. But there is only one way to do a job right in the minimum required time .

Outlining proven and time-tested steps to complete each specific PM improves productivity by:

Use SOPs to standardize maintenance work across the board and support the development of preventive maintenance checklists, and hold team members accountable for following them.

An effective preventative maintenance schedule helps avoid equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees.

In addition, a preventive maintenance checklist reduces human errors and includes important safety steps that must be taken to minimize the chance of injury.

When the maintenance plan for each piece of equipment is clearly outlined in a checklist and is followed consistently, it becomes easier to identify why something went wrong. With less variation in the way maintenance gets completed, tracing an issue back to the root cause becomes much simpler.

Clearly defined steps for each maintenance task make it much easier to estimate how long it will take to complete that task. This means that a maintenance manager will have an easier time scheduling and managing maintenance work. And the easier it is to complete maintenance work, the less downtime will become an issue.

Following a consistent Preventive Maintenance Plan can make life easier. Use this template to create your own.

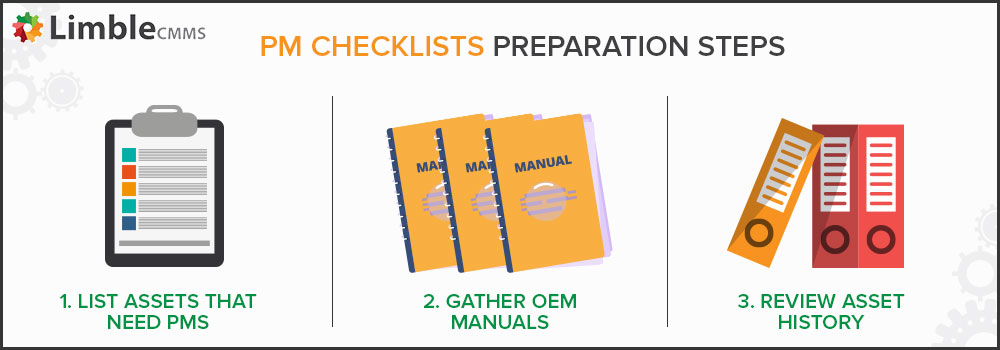

Maintenance checklists are an essential component of a successful preventive maintenance strategy . As with any PM strategy, there are three important information sources you will need; an accounting of assets, manufacturer recommendations, and asset history.

For teams who plan to create checklists for dozens of assets, it pays to be strategic. Gather necessary asset information such as make, model, location, and purchase date.

If it has been a while, this is a great time to complete an asset audit to evaluate all your assets and determine those best suited to a PM checklist. It will be document everything in one place, especially if you don’t already track assets with a preventive maintenance software or CMMS. To learn more about CMMS, check our What is a CMMS System and How Does it Work guide .

OEMs will provide the first best source of what PMs need to be completed for all your assets and how. Starting with OEM recommendations not only ensures you complete maintenance in the right way, it also helps you ensure the appropriate steps are taken every time to maintain warranties and product safety.

Over time, assets can develop unique patterns through frequent breakdowns, or use of non-original spare parts, for example. The way the maintenance needs of your equipment has changed over time must be accounted for in any preventive maintenance checklists you develop. Check your equipment maintenance logs to ensure this information is available.

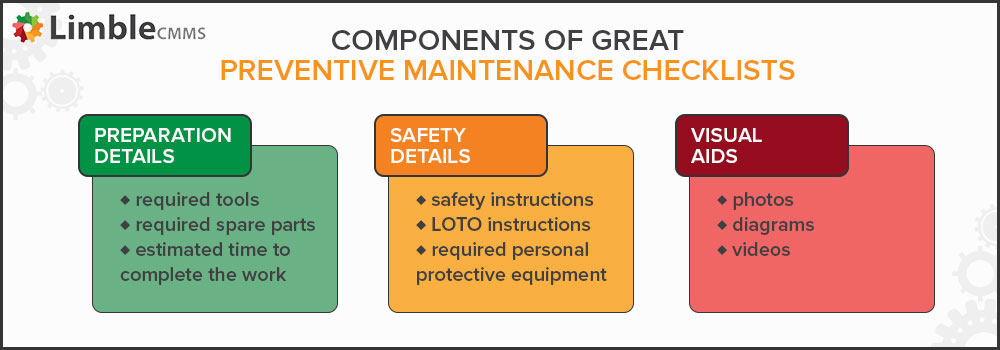

The easiest way to prepare a good PM checklist is to identify what needs to be included in each in order to facilitate your processes and workflows.

This section includes all the information your maintenance technicians need to know in order to prepare for the task. This includes:

Documenting these preparation details can help your team walk in to the task set up to complete the task effectively, and quickly without unnecessary travel to your warehouse or hardware store.

Clearly describing safety details in their own section reinforces their importance. This section should include:

The more detailed a PM checklist can be, the better. Visual aids help describe complex procedures and components more clearly. These may include:

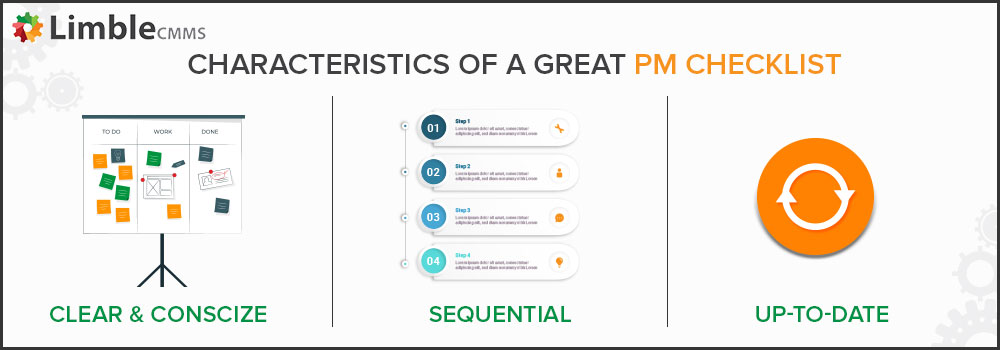

Steps to complete each PM work order should be clearly defined in each checklist. Just like standard operating procedures, it is important to use consistent language that is easy to understand.

Having too much information can be just as confusing as having too little. Finding the balance can be tricky. In general, a good PM checklist should be simple enough for a new maintenance technician to follow with minimal supervision.

Here are some tips to follow:

Step-by-step checklists should always present a list of actions in the exact order of which they should be performed. If steps need to be repeated, list them again rather than sending the reader back to an earlier step in the checklist.

Creating a PM checklist is not something you should just set and forget . Here are a few reasons why you need to update PM checklists regularly:

When you have your preventive maintenance checklist ready, run it by an experienced maintenance technician to ensure it is complete. It is also helpful to test your checklist by having a technician who was not in the process of writing it, complete a test PM.

Even for the most experienced PM checklist creator, the process becomes a lot easier with the right tools. CMMS software can make building PMs with attached checklists simple, and completing them even simpler.

The historical data stored by CMMS systems is an invaluable resource for creating checklists tailored to your exact assets. In addition, the checklist functionality built into most CMMS systems requires sequential step completion and documentation as the task is in progress. This further streamlines the management and accountability process, and makes every step trackable, and reportable for future analysis and initiatives.

A PM checklist is the Google Maps (or Waze, or even Mapquest if that is your thing) for any successful preventive maintenance program. It takes the guesswork out of preventive maintenance tasks and ensures consistency, quality, preparedness, and productivity. By endowing your maintenance team with the step-by-step best practices for all their routine maintenance activities, you provide them with the freedom to be successful and productive in their roles.

A CMMS system serves as the central repository for all your maintenance work, and is the tool that can guide your maintenance team through each step of a checklist and hold them accountable for completion. To see for yourself what Limble can do for you, schedule a quick product demo or start a free trial .